News, Industry News, Cargo Terminals, Regulators

FAA SAFO – Transport of Heavy Vehicle Special Cargo Loads

On 17 May, the FAA issued SAFO13005, a Safety Alert for Operators covering the transport of Heavy Vehicle Special Cargo Loads. ULD CARE considers this document to be of such importance that it is our lead article in this issue of our newsletter.

What is a SAFO?

A full introduction to SAFO’s can be found at: http://www.faa.gov/other_visit/aviation_industry/airline_operators/airline_safety/safo/ and to quote a key section:

“Each SAFO contains important safety information and may contain recommended actions. SAFO content should be especially valuable to air carriers in meeting their statutory duty to provide service with the highest possible degree of safety in the public interest. The information and recommendations in a SAFO are often time critical.”

The SAFO relating to Heavy Vehicle Cargo Loads can be found at: http://www.faa.gov/other_visit/aviation_industry/airline_operators/airline_safety/safo/all_safos/media/2013/SAFO13005.pdf

The board of ULD CARE highly recommends that every one of its members take the time to read this document. Of course, many of you may not have anything to do with moving heavy vehicles or other such items by air, many may not even operate freighter aircraft, but that does not mean that a great deal of the contents of the SAFO does not have some bearing on everyday air cargo operations.

So what is this to do with ULD CARE? Everything !!! Because the publication of this SAFO adds another regulatory requirement into the air cargo industry.

What do we mean?

The loading and restraint of cargo on an aircraft is always subject to the requirements of the aircraft weight and balance manual (WBM) which defines operating requirements. Airlines know that they must operate their aircraft according to the WBM that includes minimum performance standards for ULDs. The use of ULDs on aircraft has always been regulated no differently to any other item of aircraft equipment.

In 2005, in response to findings by the US NTSB into an accident involving a cargo aircraft the FAA published AC 120-85, (http://rgl.faa.gov/Regulatory_and_Guidance_Library/rgAdvisoryCircular.nsf/list/AC%20120-85/$FILE/120-85.pdf ) This document added considerably more detailed guidance on cargo operations than can be found in the more general FAR’s spelling out clearly best practices for air cargo operations including extensive material on ULD operations.

Now, in 2013, we have the FAA issuing a SAFO addressing how to go about loading and securing heavy vehicles on aircraft, zeroing in even more specifically to one aspect of cargo operations.

These developments are of considerable interest to ULD CARE but we cannot help but ask ourselves, how will these latest regulatory requirements manage to become part of normal operating practice across the far flung corners of the global air cargo industry? With cargo aircraft flying from Abu Dhabi to Zurich and everywhere in between, and being handled and loaded with cargo by a whole host of sub contract service providers and other parties as illustrated in this widely used illustration; there is a long gap between the regulators and those who need to respond to the regulations.

These developments are of considerable interest to ULD CARE but we cannot help but ask ourselves, how will these latest regulatory requirements manage to become part of normal operating practice across the far flung corners of the global air cargo industry? With cargo aircraft flying from Abu Dhabi to Zurich and everywhere in between, and being handled and loaded with cargo by a whole host of sub contract service providers and other parties as illustrated in this widely used illustration; there is a long gap between the regulators and those who need to respond to the regulations.

ULD CARE is perhaps the best placed organization to help bridge this chasm, one of our tools being this newsletter, and there are two very specific and related themes ULD CARE wishes to address at this moment.

The first is the widespread lack of training and awareness in the air cargo industry when it comes to ULDs. Many are not even aware that the ULD has any kind of airworthiness role, seeing ULDs instead as just a box to move cargo around. Not only does this result in widespread misuse and damage to ULDs but more critically, far too many ULD operations are carried out in a manner that does not deliver the required levels of airworthiness. Many organizations see no good reason to invest in training, and to some extent who can blame them, as they don’t suffer the results of sub standard operations, airlines do. This SAFO makes many references to straps or tie downs, yet to the vast majority of this industry, without any training or even basic awareness of the safety critical nature of cargo loading operations, a cargo strap, as shown here, is simply an item often found lying on the cargo shed floor, waiting to be picked up and used by anybody needing a strap without any understanding of the safety critical function this item must perform.

The first is the widespread lack of training and awareness in the air cargo industry when it comes to ULDs. Many are not even aware that the ULD has any kind of airworthiness role, seeing ULDs instead as just a box to move cargo around. Not only does this result in widespread misuse and damage to ULDs but more critically, far too many ULD operations are carried out in a manner that does not deliver the required levels of airworthiness. Many organizations see no good reason to invest in training, and to some extent who can blame them, as they don’t suffer the results of sub standard operations, airlines do. This SAFO makes many references to straps or tie downs, yet to the vast majority of this industry, without any training or even basic awareness of the safety critical nature of cargo loading operations, a cargo strap, as shown here, is simply an item often found lying on the cargo shed floor, waiting to be picked up and used by anybody needing a strap without any understanding of the safety critical function this item must perform.

Now, to be fair to airlines, and in particular US airlines, many have made significant efforts to address the issue of training, US airlines actually have no choice, as AC120-85 Sec 8 states clearly that airline and subcontract staff shall be trained but for individual airlines to change a global culture that believes ULD operations can be learnt on the job through the transfer of tribal knowledge is an extraordinary challenge and in spite of best efforts ignorance of important aspects of ULD operations predominates.

The second theme we wish to highlight is that those ULDs or parts of ULDs that are made of textiles receive an even lower standard of care and attention than -say- aluminum containers.

FAA AC 120-85 Sec. 234,235,236 makes very specific mention of cargo straps and nets, while SAFO 13005 has a very clear focus on cargo straps, yet the worrying fact in today’s air cargo industry is that while the operational standards of ULDs in general leaves a lot to be desired, when it comes to the use of ULDs constructed of textiles ( straps, nets, container doors etc.) the standard drops right off the scale, for whatever reason the air cargo industry seems to believe that an item made of textile is unworthy of proper attention and unimportant as far as flight safety is concerned. The use of containers’ door covers and nets, pallet nets and cargo straps in totally unacceptable condition is widespread. This is made worse by inappropriate use of sharp implements like knives when working with ULD nets as well as improper storage and lack of concern about degradation and lifetime limits of textile items.

FAA AC 120-85 Sec. 234,235,236 makes very specific mention of cargo straps and nets, while SAFO 13005 has a very clear focus on cargo straps, yet the worrying fact in today’s air cargo industry is that while the operational standards of ULDs in general leaves a lot to be desired, when it comes to the use of ULDs constructed of textiles ( straps, nets, container doors etc.) the standard drops right off the scale, for whatever reason the air cargo industry seems to believe that an item made of textile is unworthy of proper attention and unimportant as far as flight safety is concerned. The use of containers’ door covers and nets, pallet nets and cargo straps in totally unacceptable condition is widespread. This is made worse by inappropriate use of sharp implements like knives when working with ULD nets as well as improper storage and lack of concern about degradation and lifetime limits of textile items.

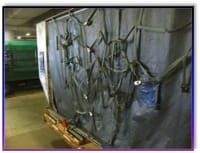

The use of containers having netted doors, as seen in this picture, with the net in a damaged condition is widespread, and for some reason the industry seems to think that a net in damaged condition is not sufficient to take the ULD out of service and send it for repair and that it can continue in service.

The SAFO specifically mentions that the mixing of different types of strap shall not be permitted. Yet, how often can one see straps from multiple airlines, easily designated by their different colors and markings, being used on the same load as shown in this picture? The industry thinks nothing of securing a piece of cargo, weighing many tons, to a pallet using straps taken from a general pile on the cargo shed floor, belonging to various airlines and of various condition, often attaching them to the seat track using 2 stud fittings picked up out of another pile.

The SAFO specifically mentions that the mixing of different types of strap shall not be permitted. Yet, how often can one see straps from multiple airlines, easily designated by their different colors and markings, being used on the same load as shown in this picture? The industry thinks nothing of securing a piece of cargo, weighing many tons, to a pallet using straps taken from a general pile on the cargo shed floor, belonging to various airlines and of various condition, often attaching them to the seat track using 2 stud fittings picked up out of another pile.

A common solution to enable continued use of a damaged cargo net… pick up a loose double stud with ring off the cargo shed floor (no idea where it came from) and over-loop it into the net. Looks OK, but is it the approved solution and is it strong enough? No it is not.

A common solution to enable continued use of a damaged cargo net… pick up a loose double stud with ring off the cargo shed floor (no idea where it came from) and over-loop it into the net. Looks OK, but is it the approved solution and is it strong enough? No it is not.

We could go on for many pages showing examples of improper use of textile components used in ULD, but the three shown here suffice to make the point, the air cargo industry urgently needs both to stop damaging the textile components of ULD equipment and start recognizing that they may not use any textile items that are not in an airworthy condition, without this simple step the regulations can never be effective.

ULD CARE stands for 4 components of ULD operations

- Compliance

- Airworthiness

- Regulation

- Education

and all 4 of these components have a part to play in addressing the issues highlighted above. The regulators (the FAA in this case) have spoken, with AC 120-85 and with the recent SAFO 13005. IATA has published the ULD Regulations (and we can expect 2nd edition to contain additional material on the use of cargo straps), so there can be no excuse that there isn’t sufficient guidance material, but without a global industry wide uptake these will remain just regulations.

ULD CARE is neither a regulator nor a trainer, but we can add value by communicating to the wider industry on important, safety critical issues such as those highlighted here, that anyone working with ULDs should be taking seriously.

Once again, may we use this opportunity to pass this message on to your colleagues, service providers and customers who may find this important information to be of inte