CARE, ULD Service providers, Safety

Certified and Non Certified ULD explained

One of the fairly common questions that comes up around ULD is “ What’s all this about Certified and Non-Certified ULD, what does this mean and how does it affect ULD operations?” This article sets out to explain in as simple terms as possible what are the differences between these two categories of ULD, why there is a need to have these two different categories and how these differences can impact on operations.

What are the differences between a Certified and a Non-Certified ULD?

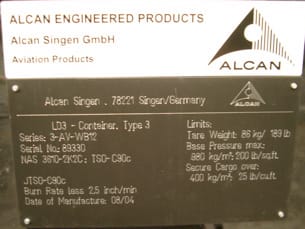

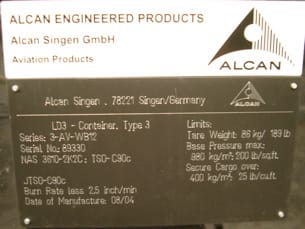

A Certified ULD is one which has been designed and tested in accordance with the requirements of the TSO C90 (TSO C172 for cargo straps) by the OEM, and where these results have been scrutinized and accepted by the appropriate aviation authority who then issues an approval letter to the manufacturer of the ULD, authorizing the approved ULD to be fitted with a TSO plate.

A Certified ULD is one which has been designed and tested in accordance with the requirements of the TSO C90 (TSO C172 for cargo straps) by the OEM, and where these results have been scrutinized and accepted by the appropriate aviation authority who then issues an approval letter to the manufacturer of the ULD, authorizing the approved ULD to be fitted with a TSO plate.

A Non-Certified ULD is one, which has not been through this procedure, and has not received any kind of assessment of its performance standards by an appropriate aviation authority.

The FAA TSO index is found at http://www.airweb.faa.gov/Regulatory_and_Guidance_Library/rgtso.nsf/MainFrame?OpenFrameSet

Why do we have these differences?

The answer to this question lies in the Weight and Balance Manual (WBM). Some aircraft do not require that the ULD have been tested to a particular standard and approved by a recognized aviation authority while other aircraft specifically require that the ULD being loaded onto that aircraft has received such an approval. This requirement is aircraft specific and the only way to be 100% certain is to consult the WBM for that particular aircraft but some general rules are applicable:

- The main deck compartments of all aircraft regardless of the manufacturer will almost certainly require the use of Certified ULD

- Airbus aircraft will generally require the use of Certified ULD in lower deck holds

- Boeing aircraft will generally not require the use of Certified ULD in lower deck holds

The WBM does not make any kind of statement requiring the use of Non-Certified in any particular aircraft, it will simply not mention the requirement for the ULD to be Certified unless that particular hold requires a Certified ULD.

How does this impact day-to-day ULD operations?

Many airlines today operate aircraft from Boeing and Airbus, and while in theory they could maintain discrete fleets of Certified and Non-Certified ULD to fulfill the needs of the two types of aircraft, practical considerations generally dictate that a single common fleet of Certified ULD be the preferred choice. Of course if an airline finds that its operations comprise entirely of aircraft that do not require the use of certified ULD, and that they will not carry out any kind of interlining or other transfers that might necessitate the loading of the ULD onto an aircraft requiring certification then a decision to use exclusively non-certified ULD could be made. In one particular case- the B767- the decision is taken out of the airline’s hands because until recently there was no straightforward method to certify LD2, LD4 and LD8 containers- a point we will cover in more detail below.

Of course it might be possible that a Non-Certified ULD, not having had to undergo the required testing of a certified ULD could be cheaper to purchase and cheaper to maintain but this is very rarely the case. The nature of the ULD supply industry is such that manufacturers design and produce both Certified and Non-Certified ULD, using the same materials, basic design concepts, and even many common parts and therefore apart from some additional documentation requirements for the Certified ULD, there is very little opportunity for a cost difference. The same situation applies when it comes to the repair and maintenance of ULD. In 99% of situations, both will be repaired in the same workshops using the same tools and the same staff, and again the only difference is that when the repaired unit leaves the workshop the Certified ULD requires the completion of a release note which confirms its airworthiness. There is no such requirement for the Non-Certified ULD.

So far no real difference between design and manufacture, or repair and maintenance. But what about actual day-to-day cargo operations? Reading that a Non-Certified ULD does not have to meet any particular strength/performance requirement one might draw the conclusion that there is no need for the ULD to undergo any kind of serviceability check before being built up and loaded to the aircraft in any old condition. However this would be overlooking some very important points:

- While the WBM may not call for the ULD to be certified it will probably contain wording to the effect that the ULD and its contents shall not present a hazard to the aircraft or its systems when loaded, putting the responsibility right back into the hands of the aircraft operator to decide what condition is acceptable or not.

- There are also strong practical/operational reasons why the Non-Certified ULD should be in a good enough condition that it can be moved over the ground support equipment and aircraft loading system and into its location in the hold without experiencing any hang-ups or causing any damage to the aircraft.

- • The Non-Certified ULD should also be in good enough condition that the door operates correctly and that the contents will be securely contained during all phases of ground and air operation.

These three points are very good reasons why Non-Certified ULD should not be considered in any manner to be inferior or accept lower standards than Certified ULD.

When some years ago IATA introduced the Operational Design Limits Notice (ODLN) for all ULD Non-Certified ULD were provided with a much simplified ODLN that provided a general guidance as to the acceptable condition of the ULD compared to the much more detailed guidance provided for a Certified ULD. However in a later revision the ULD Panel decided that such a differentiation was not appropriate, and that regardless of whether a ULD is Certified or Non-Certified it should be required to undergo the same level of serviceability check before use.

Other Considerations

LD2, LD4 and LD8 (DPE, DQP and DQF) containers have always been somewhat of a special case. The base and contour dimensions of these three container types are specifically matched to the B767 aircraft and it is not particularly common to find these types of containers being loaded into other aircraft. At the same time when the documentation that supports the certification of ULD was first set up around 40+ years ago, there was no mention of any requirements for LD2, LD4 and LD8 containers, and in the absence of this data, there was no straightforward manner to make Certified versions. This resulted in these three types of container being the most commonly found Non-Certified ULD around the industry.

LD2, LD4 and LD8 (DPE, DQP and DQF) containers have always been somewhat of a special case. The base and contour dimensions of these three container types are specifically matched to the B767 aircraft and it is not particularly common to find these types of containers being loaded into other aircraft. At the same time when the documentation that supports the certification of ULD was first set up around 40+ years ago, there was no mention of any requirements for LD2, LD4 and LD8 containers, and in the absence of this data, there was no straightforward manner to make Certified versions. This resulted in these three types of container being the most commonly found Non-Certified ULD around the industry.

Pallets and nets present a further complication. Although the list of ULD categories contained in Section 4 of the ULDR makes reference to Non-Certified pallets and Non-Certified nets, the use of these items is rather questionable. Can a Non-Certified pallet, loaded with cargo and covered with a Non-Certified net really be capable of preventing any kind of hazard to the aircraft or its systems?

Certified and Non-Certified ULD are indeed different when it comes to the paperwork, but when it comes to operational matters they both deserve the same levels of careful handling and more importantly their suitability for use on any particular aircraft must always be in compliance with the Weight and Balance Manual.